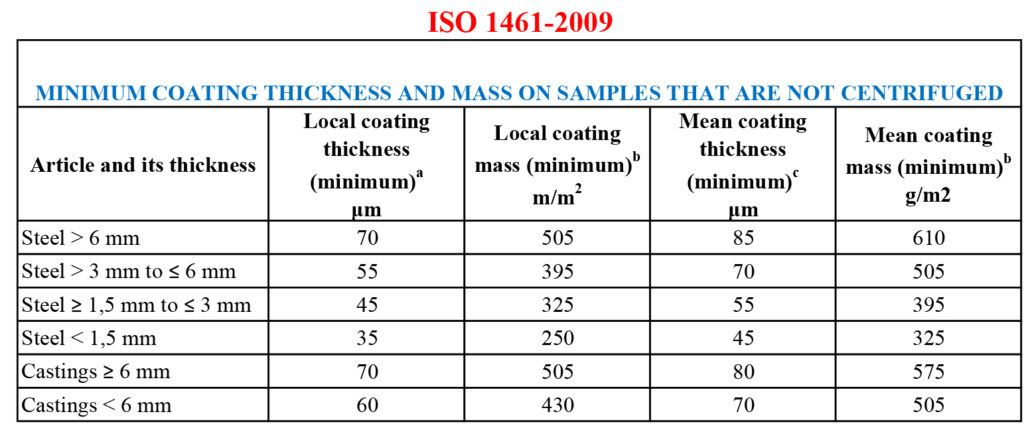

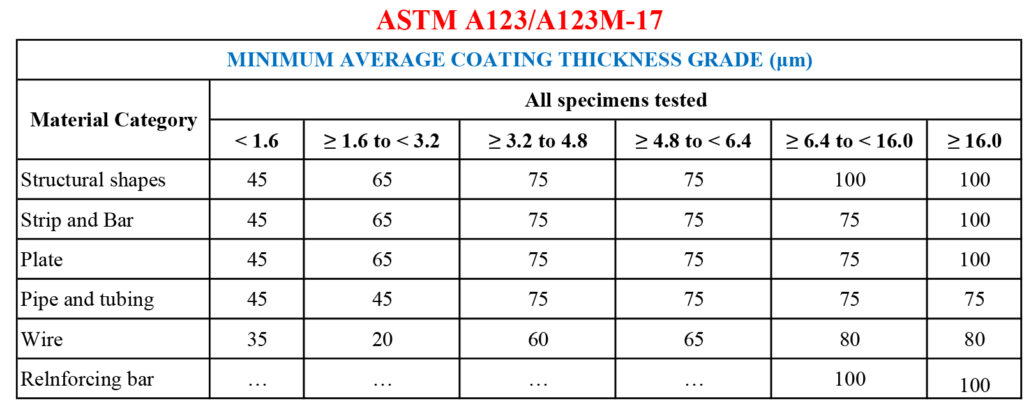

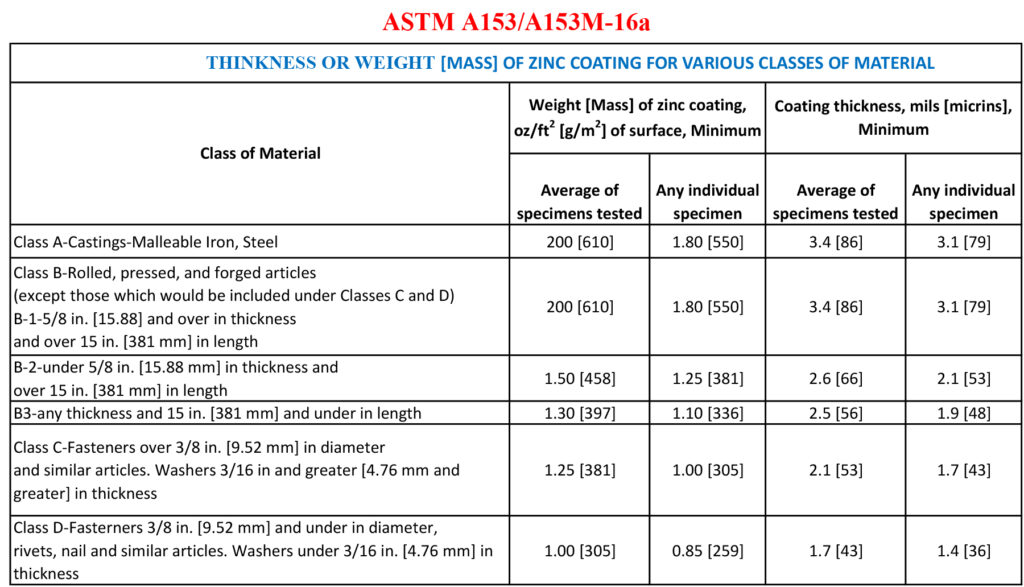

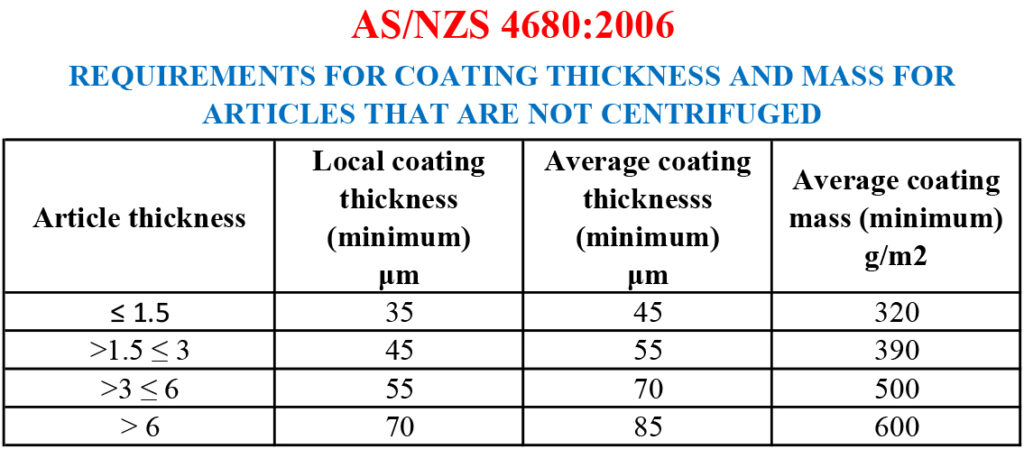

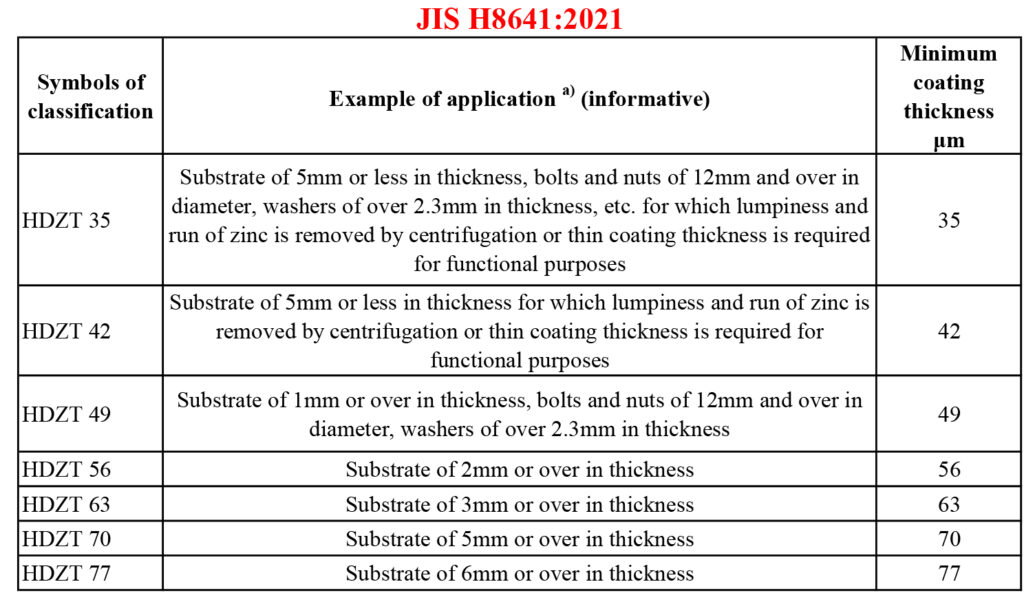

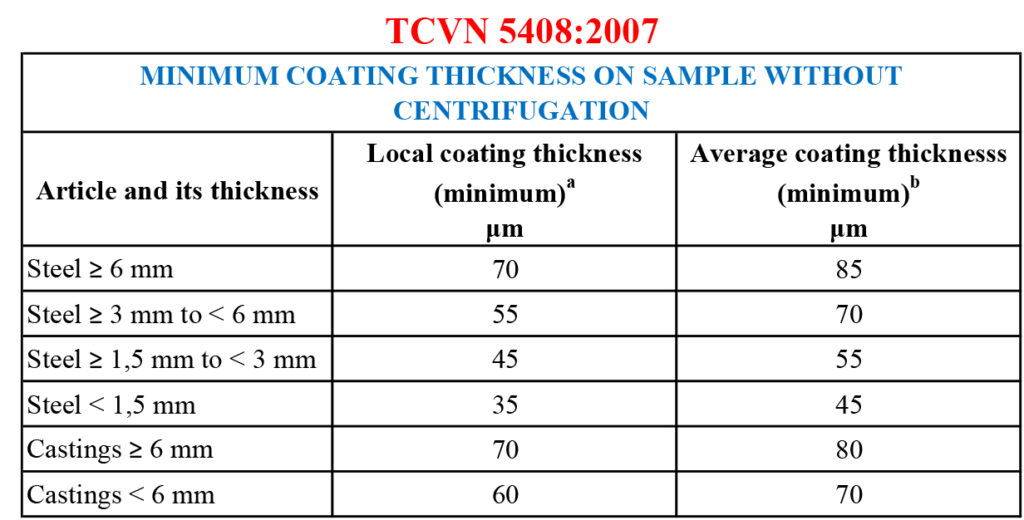

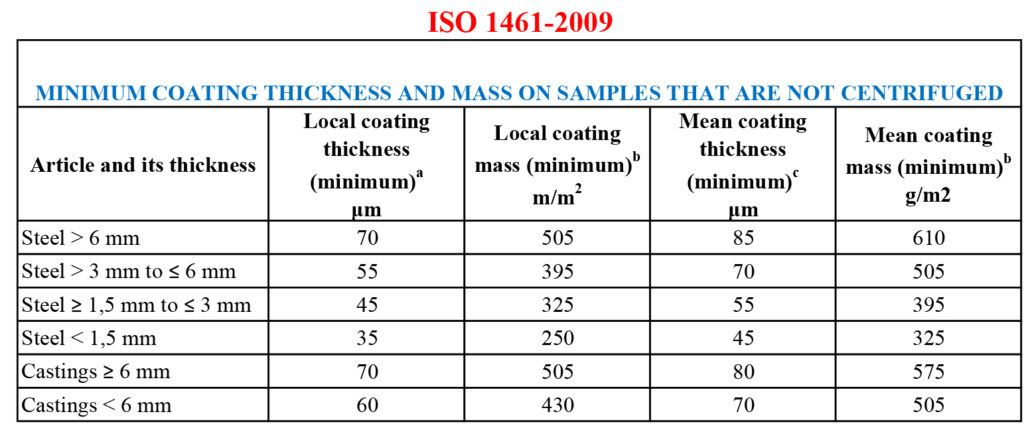

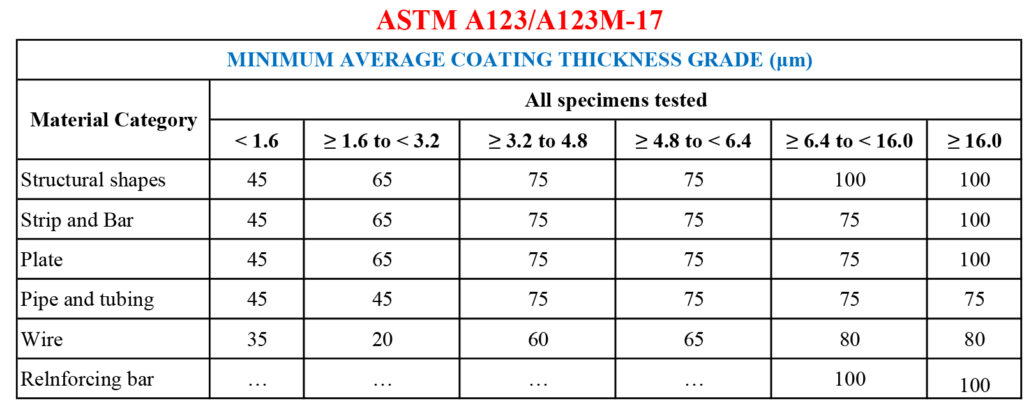

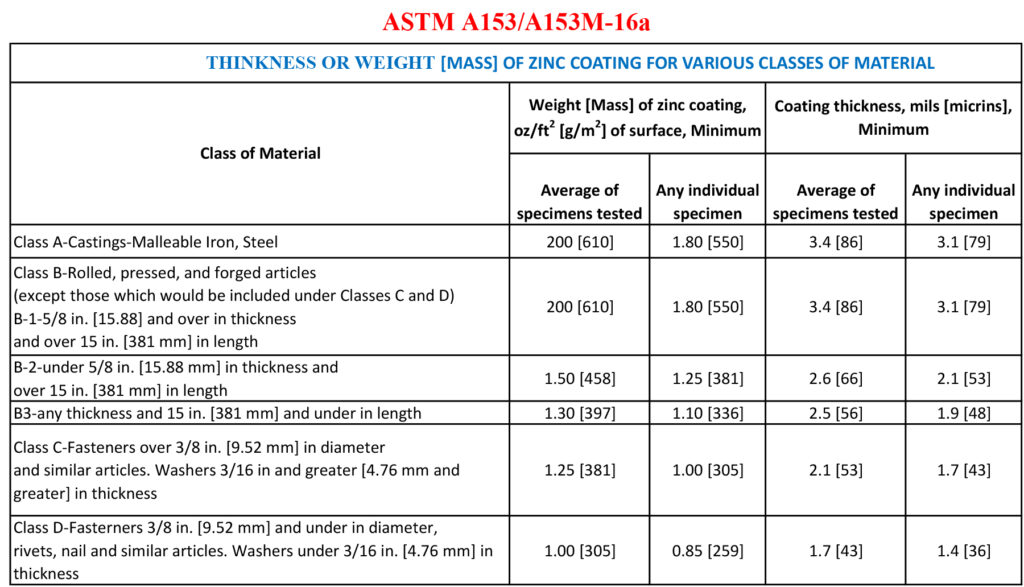

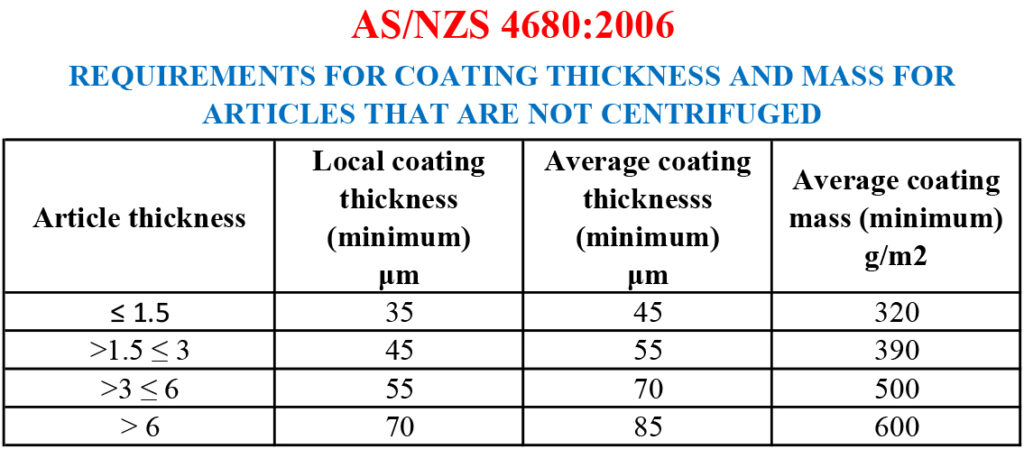

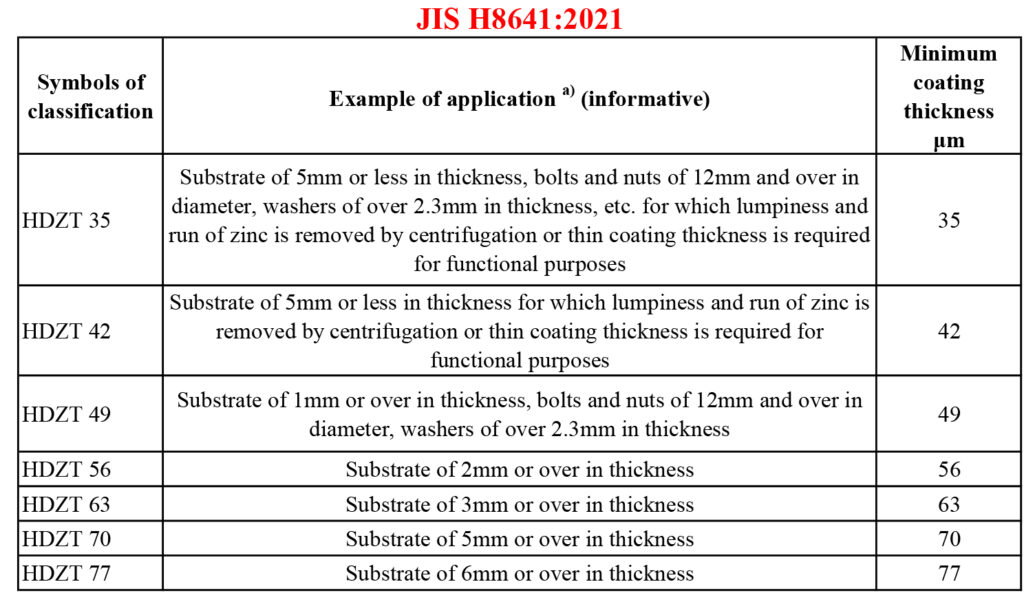

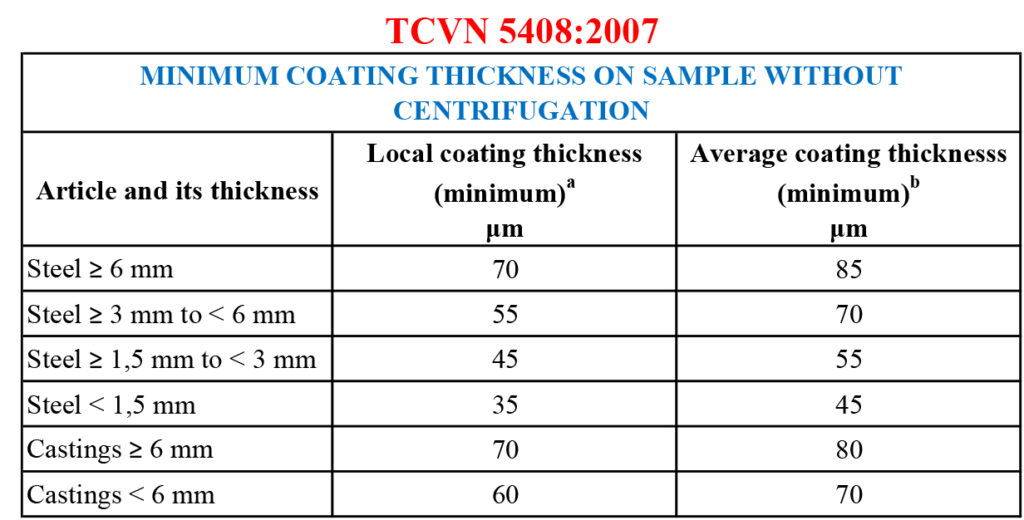

THICKNESS STANDARDS IN HOT DIP GALVANIZER

THICKNESS STANDARDS IN HOT DIP GALVANIZER

Let us help you…

Do you like to leave feedback or give us suggestions? Do you want to receive advice or support information about Chien You products?

Please leave contact information for Chien You to quickly feedback after receiving your information!

Address: No. 12 3A Street – Bien Hoa Industrial Park 2 – Dong Nai

Phone: 0942 977 988 – (0251) 3833019

Fax: (0251) 383 2912

Email: info@chienyouvn.com

© 2025 Chien You . All rights reserved.

Follow Us